Industrial machines generally have heavy loads to lift and pull. Whether it’s excavators or farm machinery, wire rope is the rope that is used. Industrial wire ropes typically range from 3/8” (9.5mm) to 2-1/2” (63.5mm) in diameter, and besides heavy machining applications, wire ropes also serve as support cables for large static structures such as stadium roofs and bridges. Manufacturing a wire rope begins with steel wire that is anywhere from .6 to 8 millimeters in diameter. The first step is to wind several of these wires together, into a strand. How many wires per strand depends on the application of the wire. Different applications require various levels of flexibility and strength.

Wires:

Steel wires are used for wire ropes and are typically fashioned from a non-alloy carbon steel material. This metal has a carbon content of 0.5 to 0.95%, which makes it incredibly strong. As a result of its strength and durability, steel wires are able to support large tensile forces and can run over sheaves with small diameters.

Strands:

Strands are created when wires of different layers cross each other. Parallel lay strands are some of the most commonly manufactured strands. The lay length of the wire strands is generally equal to the wires of any two layers that are parallel. This means that there is linear contact. Inner layer wires support the outer layer wires along the entire length of the strand.

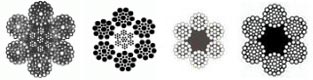

Spiral Ropes:

In essence, spiral ropes are round strands that are assembled in layers of wires that are aligned in a spiral design. Spiral ropes are constructed so that they are non-rotating, which means that that there is practically no tension under the rope torque.

Stranded rope:

Stranded ropes are comprised of several different layers of strand that are laid in multiple spiraling layers around a core. A stranded rope core can come in three different types: fiber cores, wire strand cores, or independent wire rope cores. Fiber cores are the most flexible and elastic of the 3 variations, but are easily crushed. Wire strand cores are typically used for suspension and have a high tensile strength. Independent wire rope is the most durable in all types of environments.

If you are interested in learning more about wire rope, the different types of designs, or how the product is used, contact Bilco wire rope for more information and facts!

Related Reading