A Crucial Safety Perspective

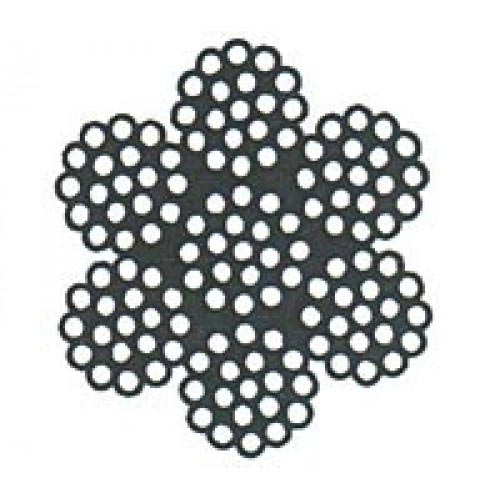

In industrial operations, wire ropes are critical in various applications, from construction to maritime activities. However, with their extensive use come significant risks, particularly abrasion, bird caging, and kinking. These issues are not just technical concerns; they threaten business operations and human safety.

In industrial operations, wire ropes are critical in various applications, from construction to maritime activities. However, with their extensive use come significant risks, particularly abrasion, bird caging, and kinking. These issues are not just technical concerns; they threaten business operations and human safety.

The Dangers Posed by Wire Rope Damages

Abrasion in wire ropes typically occurs when the ropes rub against external surfaces. This continuous friction wears away the outer wire strands, weakening ropes and making them prone to snapping unexpectedly. This can mean halted operations, equipment damage, and considerable financial losses in a business context. From a human safety perspective, the sudden failure of an abraded wire rope can lead to catastrophic accidents, potentially causing severe injuries or even fatalities.

Bird caging represents another critical issue. This structural failure happens when the rope strands open in a pattern resembling a birdcage. It often results from the sudden release of tension or incorrect handling, leading to internal damage and a significant reduction in the rope's strength. For businesses, bird caging can cause unexpected downtime and costly repairs. More alarmingly, it can lead to dangerous work conditions where the integrity of loads being hoisted or supported is compromised.

Kinking in wire ropes is a deformation caused by improper handling, such as twisting or bending the rope too sharply. Once a wire rope is kinked, it can never regain its original strength or flexibility. This deformation shortens the rope's lifespan, leading to increased maintenance costs for businesses and poses a substantial safety risk. Kinked ropes are more likely to fail under stress, which can lead to accidents and jeopardize the safety of workers.

The Importance of Awareness and Prevention

Understanding the risks associated with abrasion, bird caging, and kinking in wire ropes is essential for any industry that relies on these tools. The potential damage extends beyond the immediate financial costs to include long-term business disruptions and, most critically, the safety and well-being of individuals.

Common and Unusual Circumstances Leading to Wire Rope Damages: Abrasion, Bird Caging, and Kinking

Exploring the Common and Uncommon Causes

In the intricate world of wire rope usage, understanding the common and rare causes of abrasion, bird caging, and kinking is vital for maintaining safety and efficiency. This article dives into the various scenarios, both typical and unexpected, that can lead to these detrimental conditions.

Bird Caging: A Structural Nightmare

Common Causes:

- Sudden Release of Tension: One of the primary causes of bird caging in wire ropes is the sudden release of tension. This scenario is common in lifting operations where a heavy load is unexpectedly dropped or released. The abrupt change in pressure can cause the wire rope strands to expand outward, resembling a bird cage.

- Incorrectly Spooled Ropes: Improper spooling is another significant factor contributing to bird caging. When a wire rope is wound under tension on drums or pulleys and then suddenly released, it can lose its uniform structure, leading to the strands flaring out. This is especially prevalent in scenarios where the spooling and unspooling processes are not monitored closely or done incorrectly.

Unusual Scenarios:

- Equipment Malfunctions: Mechanical failures in hoisting or lifting equipment can unexpectedly alter the tension in a wire rope. For instance, if a winch malfunctions or a load is inadvertently released, it can instantly relieve tension in the rope, causing bird caging. This situation is hazardous as it often occurs without warning, resulting in severe damage to the rope and potential safety hazards.

- Overloading and Underloading: Sometimes, bird caging can be caused by irregularities in load distribution, such as overloading or underloading the wire rope. These conditions can put uneven stress on the rope, leading to distortion of its structure.

- Incorrect Rope Design or Material: Using a wire rope unsuited for the specific application or load requirements can also lead to bird caging. Ropes with inappropriate design or material composition may not be able to withstand the stresses of certain operations, causing them to deform.

Abrasion: The Everyday Wear and Tear of Wire Ropes

Common Causes:

- Frequent Contact with Rough Surfaces: The most prevalent cause of abrasion in wire ropes is continuous contact with hard, abrasive materials. This scenario is typical in industries like construction and mining, where wire ropes are often in contact with rough surfaces such as rocks, metal edges, and other coarse materials. These interactions gradually wear down the rope, stripping away its protective layers.

- Incorrect Usage or Poor Handling: Improper spooling of wire ropes on drums or pulleys significantly contributes to abrasion. If the rope is not wound or unwound correctly, it can rub against itself or parts of the equipment, leading to increased wear. Similarly, dragging the rope over surfaces or through materials it is not designed for can cause external damage.

- Environmental Factors: Exposure to harsh environments is another key factor. Elements like sand, dirt, grit, and even chemical exposures can accelerate the wear and tear on the rope. These factors can be particularly aggressive in maritime or industrial environments, where corrosive elements like salt water or chemicals are prevalent.

Unusual Scenarios:

- Accidental Dragging: In some instances, wire ropes may become accidentally entangled with moving vehicles or machinery, causing them to be dragged across uneven or harsh surfaces. This can lead to severe and unstable abrasion, compromising the rope's integrity much more rapidly than normal wear and tear.

- Exposure to Extreme Temperatures: While less common, extreme temperatures can also contribute to abrasion. Elevated temperatures can make the rope more susceptible to wear, while extremely low temperatures might make it brittle, increasing the risk of abrasion during everyday use.

Kinking: The Result of Mistreatment

Common Causes:

Sharp Bends and Twists: Kinking is commonly caused by bending the rope too sharply or twisting it during use or spooling. This is often seen in hurried operations where ropes are not handled carefully.

Improper Storage: Storing wire ropes without proper coiling or on uneven surfaces can lead to kinks.

Unusual Scenarios:

Accidental Entanglement: There are instances where wire ropes get entangled with moving parts of machinery or other equipment, leading to sharp bends that cause kinking.

Vigilance and Proper Handling

Typical and unusual causes of abrasion, bird caging, and kinking in wire ropes highlight the importance of vigilant handling, proper usage, and regular inspections. These measures are crucial for prolonging the life of wire ropes and ensuring operational safety and efficiency. The next article will focus on preventive measures and best practices to avoid these damaging conditions.

Mastering the Art of Preventing Bird Caging, Abrasion, and Kinking in Industrial Wire Ropes

In the demanding world of industrial applications, mastering the prevention of wire rope issues like bird caging, abrasion, and kinking is crucial. While essential maintenance and handling practices are foundational, users must adopt advanced strategies to ensure peak performance and safety.

Basic Tips

- Regular Inspections: Perform thorough visual and tactile inspections for any signs of wear, distortion, or damage.

- Proper Storage: Store wire ropes properly coiled, away from moisture and corrosive materials.

- Correct Usage: Ensure wire ropes are used within their specified load capacities and environmental conditions.

Advanced Tips

Implement Predictive Maintenance Technology:

Utilize acoustic emission testing, a non-destructive method that listens for sound waves emitted by cracks or faults within the rope, enabling early detection of internal damages that are invisible to the naked eye. Magnetic rope testing, another sophisticated technique, involves passing a magnetic field through the rope to identify surface and subsurface anomalies such as broken wires or corrosion. Integrating these technologies into routine maintenance schedules can dramatically reduce the risk of unexpected failures.

Real-time monitoring systems with sensors provide continuous data on factors such as rope tension, bends, and environmental conditions. These systems immediately identify abnormal patterns or stress points, prompting timely maintenance or operational adjustments. This proactive approach is particularly beneficial in environments with variable loads or extreme conditions, ensuring consistent rope integrity.

Customized Rope Design and Material Selection:

Engaging with manufacturers to create wire ropes with advanced coatings, such as thermoplastic polyurethane or specialized lubricants, enhances abrasion resistance, especially in environments with high particulate matter or corrosive elements. Selecting ropes made from high-grade stainless steel or galvanized steel can significantly increase their resilience in maritime or chemically aggressive settings. These material choices are crucial for applications where standard ropes would rapidly degrade.

Ropes designed with compacted strands offer a smoother exterior surface, reducing the point of contact wear and increasing crush resistance, which is vital in heavy lifting scenarios. Ropes with plastic-infused cores provide additional internal support, minimizing the risk of bird caging by maintaining the structural integrity under fluctuating tension. These design features are advantageous in complex lifting mechanisms or variable load dynamics applications.

Advanced Handling and Operational Techniques:

Tension spooling, a technique where the rope is wound onto drums under controlled pressure, ensures uniform winding and prevents loose layers that can lead to internal damage or distortions like bird caging. This technique is essential for deep-sea lifting or crane operations were inconsistent spooling could have severe consequences. Regularly recalibrating tension settings based on operational requirements can further optimize rope performance.

Employing dynamic load testing, which involves applying varying loads to the rope in controlled environments, helps understand its behavior under different stress conditions. This testing and simulation model can reveal potential weak points or stress accumulations, guiding adjustments in handling techniques. For instance, modifying lifting angles or pulley systems in response to these findings can significantly reduce abrasion risks in repetitive lifting cycles or when navigating complex pulley systems.

Related Reading