UNDERSTANDING THE CORE DIFFERENCES

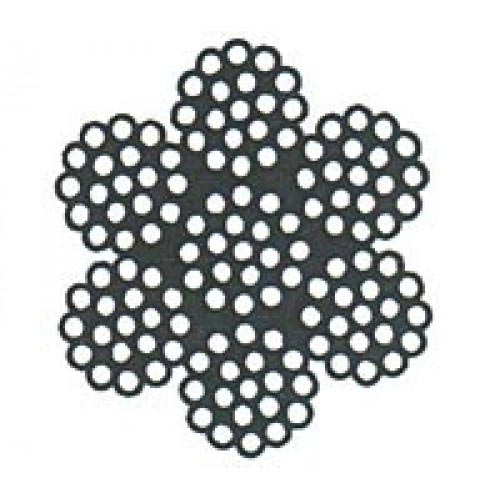

The importance of understanding forces cannot be overstated in industries that heavily rely on lifting and rigging—such as construction, maritime, and oil and gas. The two primary forces that professionals need to be familiar with are tension and compression. While both forces are involved in managing and transferring loads, their nature, mode of action, and implications, particularly for wire ropes, are distinct.

The importance of understanding forces cannot be overstated in industries that heavily rely on lifting and rigging—such as construction, maritime, and oil and gas. The two primary forces that professionals need to be familiar with are tension and compression. While both forces are involved in managing and transferring loads, their nature, mode of action, and implications, particularly for wire ropes, are distinct.

TENSION FORCE IN WIRE ROPES

Tension is created when wire ropes or cables are subjected to pulling forces from opposite ends. This force tries to stretch or elongate the wire rope along its length. The tighter the rope becomes, the higher the tension, up to the point of the rope's tensile strength.

- How is it encountered with wire ropes? When a crane lifts a load, for example, the weight of that load creates tension in the rope. This force is counteracted by the crane's lifting mechanism, maintaining equilibrium.

- How to Calculate? The formula for tension force in wire ropes refers to the lifted load's mass and g represents gravitational acceleration. However, real-world applications might require additional considerations like friction between pulleys, dynamic forces, or angular considerations in multi-rope lifting setups.

COMPRESSION FORCE IN WIRE ROPES

Compression seeks to push objects together, unlike tension, which pulls objects apart. While wire ropes are more commonly associated with tension, they also encounter compressive forces, especially when wound around drums or passing over sheaves.

- How is it encountered with wire ropes? Consider a scenario where a wire rope is wound around a drum. As the drum rotates and the rope winds around it, the underlying layers of the rope experience compression due to the weight of the rope layers above them.

- How to Calculate? Compression in the context of wire ropes is more nuanced than in solid objects. While the principle of compression (force equals pressure divided by area) holds, the variables change. For a wire rope, the pressure would be the effective load the rope layers exert, and the area would be the contact area of the rope with the drum or other ropes.

THE IMPORTANCE OF TESTING FOR WIRE ROPES

Both tension and compression forces play significant roles in determining the safety and efficacy of wire ropes in operation. Testing wire ropes for their tensile and compressive strengths ensures their reliability. Overloading or subjecting a wire rope to excessive compressive force, especially in multi-layer winding, can lead to premature wear, damage, or even catastrophic failure.

To ensure operational safety:

- Perform Regular Inspections: Wire ropes should be checked for signs of wear, damage, or fatigue.

- Know the Limits: Always be aware of a rope's rated tensile strength and compression limits, especially for specific applications like multi-layer winding.

- Use Load Monitoring Cells: Devices like the StraightPoint Load Monitoring Cells can be invaluable. They measure tension and compression forces in real time, providing operators with critical data to ensure safe operations.

Understanding tension and compression forces, and their implications on wire ropes, is essential for ensuring safe and efficient operations in industries that rely on lifting and rigging. By appreciating the differences, adhering to safety protocols, and using modern monitoring tools, risks can be minimized and the lifespan of equipment maximized. Whether you're a seasoned professional or new to the field, always prioritize safety and continuous learning about the forces at play.

Related Reading