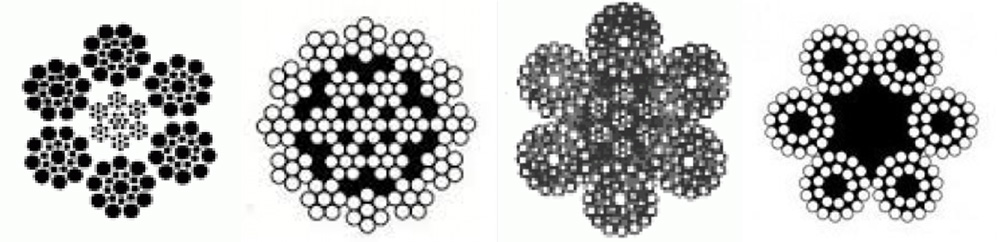

Wire rope has a similar look from afar, but there are many different types available on the market. As a result of having choices, it could make things difficult when deciding on the best rope for a specific project and application. Wire ropes are used in a multitude of applications, from aerospace to material handling. One of the most important design considerations is the specifications of rope design. The three most common specifications are 6x25, 6x36, and 7x19. The first number signifies the number of strands within a rope, and the second number determines the number of wires in each strand. For instance, with 7x19 wire ropes, there are 7 strands, and each strand is composed of 19 wires.

Shopping for wire ropes can get confusing, so you should keep in mind that cables of the same grade, size, and core all offer similar breaking strength characteristics. You will also notice that the cables share a similar weight (per each foot of cable).

Wire Rope

A 6X25 wire rope construction provides engineers with a common rope that has strength and good abrasion resistance. A 6x36 wire rope is also a common rope that has strength but is more flexible than a 6x25. Either cable is ideal for construction crews that often work with rigging and have a need for towing or maneuvering heavy objects.

A 7x19 cable is only provided in Galvanized or Stainless Steel. This cable is flexible and is only used in non-critical and non-lifting applications.

Related Reading