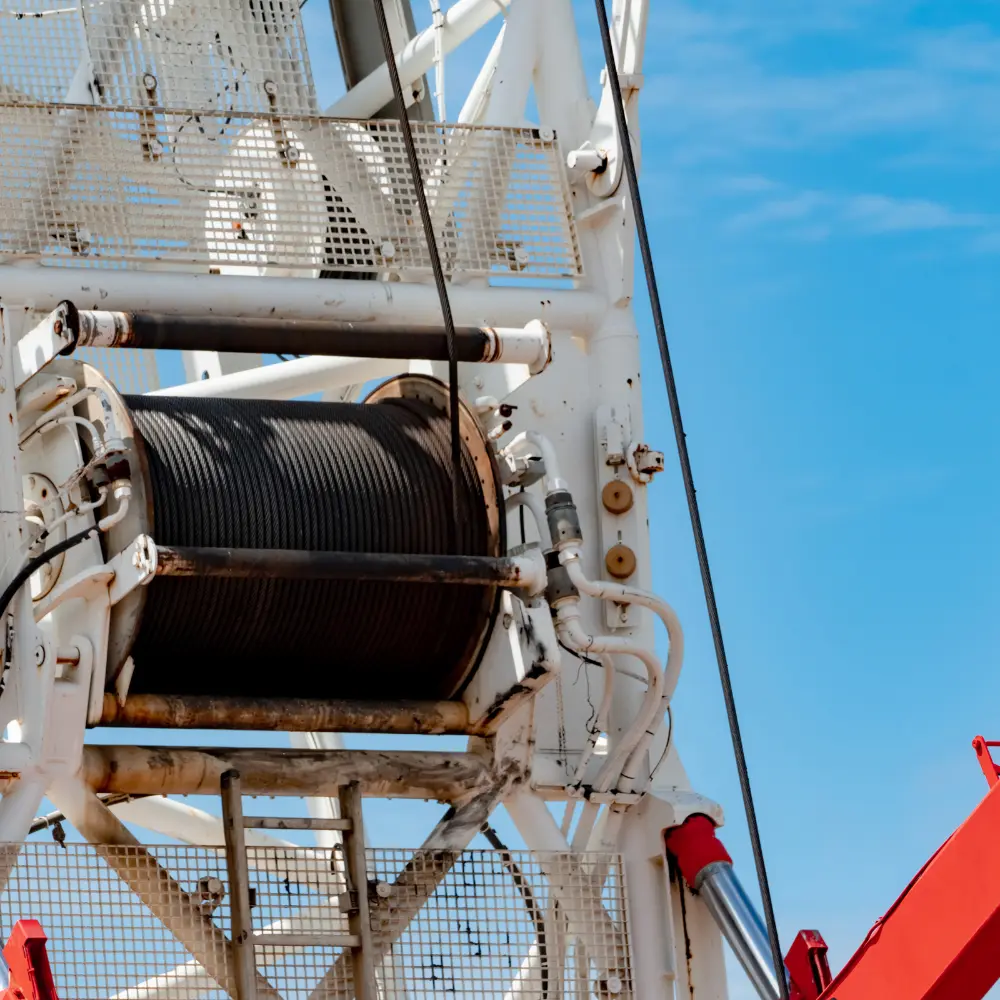

Wire ropes, engineered for their durability and strength, are fundamental in operations where failure is not an option, such as offshore mooring systems. However, their integrity can be compromised by chaser-induced damage, a specific form of degradation during anchor recovery. This damage is detrimental to the rope's structural integrity and poses a significant safety risk. Here, we delve into a detailed exploration of chaser-induced damage and propose precise strategies to mitigate its impact.

Wire ropes, engineered for their durability and strength, are fundamental in operations where failure is not an option, such as offshore mooring systems. However, their integrity can be compromised by chaser-induced damage, a specific form of degradation during anchor recovery. This damage is detrimental to the rope's structural integrity and poses a significant safety risk. Here, we delve into a detailed exploration of chaser-induced damage and propose precise strategies to mitigate its impact.

The Mechanism Behind Chaser-Induced Damage

Chaser-induced damage results from the recovery process used for mooring anchors when traditional methods are not feasible. The process employs a chaser, a large steel hook, which slides along the wire rope, exerting high contact pressures and friction. This action can cause local temperatures on the wire rope surface to spike, leading to a phase transformation of the steel from its original structure to austenite. Rapid cooling, assisted by the cold seawater, transforms the austenite to martensite, a hard and brittle phase. This martensitic phase is pre-stressed and significantly more susceptible to fatigue crack initiation, reducing the rope's fatigue life and potentially leading to catastrophic failure.

Targeted Mitigation Strategies

Several targeted strategies can be implemented to address the risk of chaser-induced damage and ensure the operational integrity and safety of wire ropes.

- Transition to Roller Chasers: Moving away from traditional hooked chasers to designs incorporating rollers can significantly mitigate the slip-stick motion that generates damaging heat. Roller chasers are designed to distribute contact pressure more evenly and reduce friction, thus lowering the risk of inducing high temperatures and subsequent metallurgical transformations in the rope.

- Improved Anchor Pendant Handling: Adopting advanced anchor pendant management techniques, such as deploying the anchor with a clump weight and precise position marking, eliminates the need for direct rope contact by chasers. Modern navigational technology allows for accurate grappling and recovery of the anchor pendant, minimizing the potential for rope damage.

- Enhanced Inspection and Real-time Monitoring: Rigorous inspection regimes, complemented by real-time monitoring technologies, are crucial for the early detection of chaser-induced damage. Techniques such as electromagnetic testing can identify internal changes and damage not visible on the rope's exterior, allowing for timely maintenance or replacement before failure occurs.

- Material and Construction Innovations: Research into wire rope materials and construction methods that increase resistance to chaser-induced damage is essential. Developing ropes with improved surface hardness and core toughness could resist martensite formation and withstand the mechanical stresses induced by chasers.

- Operational Best Practices and Training: Educating and training the operational personnel on the risks of chaser-induced damage and the importance of careful handling during anchor recovery can play a significant role in prevention. Understanding the mechanics of damage and implementing best practices will help mitigate the risk at the source.

Chaser-induced damage is a complex issue that risks the integrity and reliability of wire ropes in critical applications. Understanding the underlying mechanisms and implementing a multifaceted approach to mitigation can significantly reduce the occurrence of such damage. The strategies outlined offer a roadmap towards enhancing the safety, reliability, and lifespan of wire ropes, ensuring they continue to perform their vital roles in offshore and other high-stakes environments.

Related Reading