At Bilco Group, we know that disposing of damaged rigging equipment is more than throwing it in the trash. Wire ropes, chain slings, and synthetic slings must be taken out of service and rendered unusable to prevent them from being mistakenly reused. Unlike inspection requirements, there are no detailed disposal standards from OSHA or ASME. Instead, safety programs and university guidelines advise that damaged rigging be cut up, deformed, or otherwise destroyed before it is recycled or discarded. Leaving a condemned sling intact invites unauthorized use and exposes companies to liability if the sling fails. Proper disposal helps safety managers develop a responsible end�of�life process.

Why Disposal Procedures Matter

Rigging components must be removed from service when they no longer meet safety criteria. OSHA’s rigging standard lists defects that trigger immediate removal of slings, including abnormal wear, broken fibers, and distorted hardware for natural and synthetic fiber rope slings, and acid burns, melting, tears, or broken stitches for synthetic web slings. Similar criteria apply to wire rope slings, such as severe corrosion, kinking, bird caging, and excessive broken wires. Once a sling is condemned, simply discarding it intact creates risk; scavengers may salvage the rope for unauthorized use, leading to accidents. University programs for crane safety, therefore, require that damaged rigging be removed from service and rendered unusable before disposal.

Proper disposal is part of a comprehensive safety culture. A condemned sling tossed into a dumpster may be retrieved and used by someone unaware of its defects. If that sling fails during a lift, the original owner could be held liable for the resulting injury or property damage.

By dismantling and defacing the sling before discarding it, rigging managers ensure that worn equipment cannot be repurposed. Documenting the retirement process also demonstrates due diligence to regulators and insurance carriers.

Removal and Rendering Gear Unusable

Follow these steps to retire and dispose of damaged rigging safely.

- Confirm removal criteria. Before any destruction, verify that the sling is indeed condemned. Refer to OSHA’s guidelines for removal: broken or cut fibers on fiber rope slings, acid or caustic burns on synthetic web slings, and broken wires, severe corrosion, kinks, or bird caging on wire rope. Record the reason for retirement in inspection logs.

- Protect yourself. Broken wires can cause punctures and lacerations; rust and contaminants may pose health hazards. Wear gloves, eye protection, long sleeves, and other appropriate personal protective equipment to avoid injury while handling damaged gear.

- Remove identification and capacity markings. Detach or destroy sling tags, ratings plates, and other identification so the capacity cannot be misrepresented. Removing tags prevents someone from reusing or certifying the sling in error.

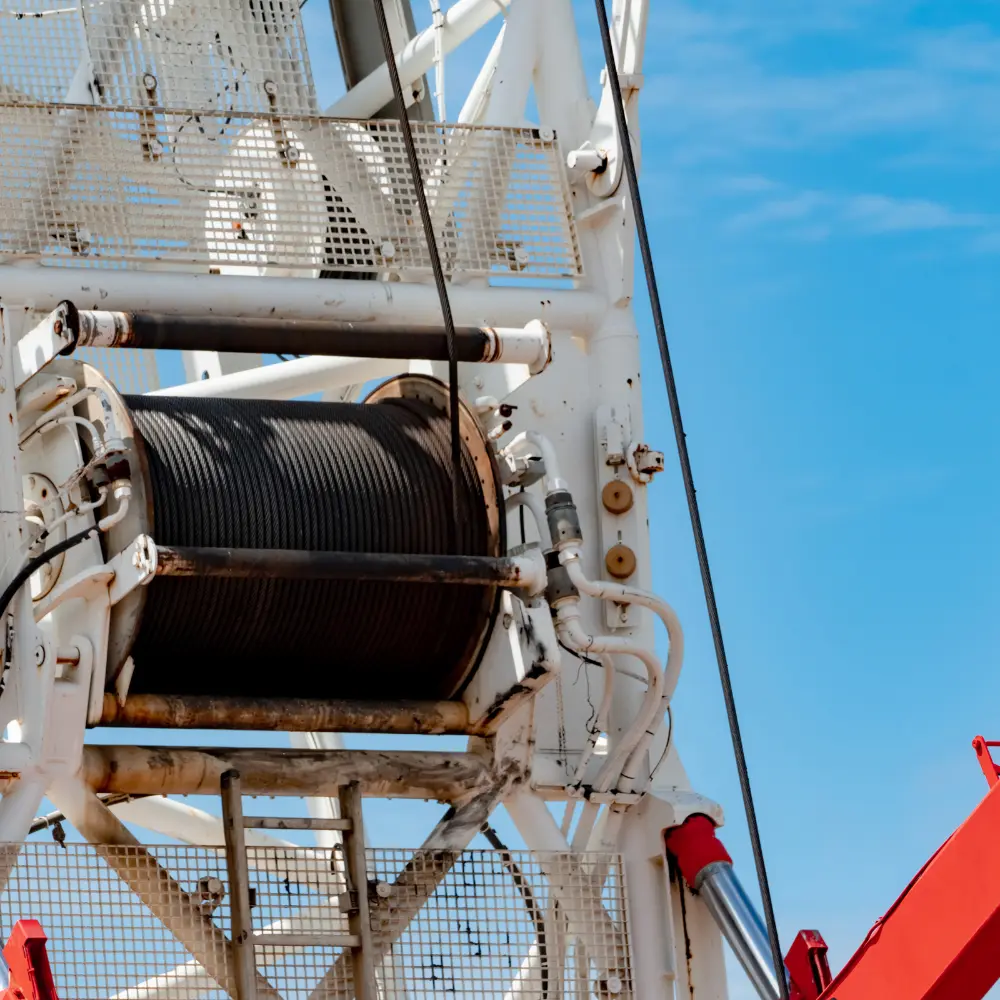

- Dismantle and destroy the sling. Cut wire rope into short sections—typically three to four feet—and deform the eyes or fittings to prevent re�splicing. For chain slings, remove hooks and cut the chain into short lengths so it cannot be reassembled. Synthetic slings should be cut through all stitching and fabric layers, and the eyes should be sliced or melted so they cannot be looped. This physical destruction ensures the item cannot be used again.

- Segregate and recycle responsibly. Separate steel and alloy components from synthetic materials. Deliver scrap metal to authorized recyclers; dispose of synthetic textiles according to local waste regulations, or contact manufacturers that offer take�back programs. Maintain documentation of disposals, including dates, methods, and destinations, to demonstrate compliance during audits.

Take Care of Your Wire Ropes During Disposal

Disposing of damaged rigging gear is an essential part of a disciplined safety program. OSHA and ASME provide clear removal criteria but stop short of detailing how to destroy and discard condemned equipment. Bilco Group follows the guidance of safety agencies and universities: once a sling is removed from service, it must be dismantled and rendered unusable before being recycled or discarded.

Proper disposal protects workers from unknowingly using defective slings and shields companies from liability if salvaged gear fails. The process begins with confirming that a sling meets removal criteria and ends with segregating and recycling materials responsibly.

Throughout, rigging managers must document their actions and equip personnel with the training and protective equipment needed to work safely. By incorporating these practices into their rigging management plans, organizations can close the loop on equipment life cycles and demonstrate their commitment to safety and environmental responsibility.

Related Reading