Extreme environments can damage rigging equipment through heat, chemicals, corrosion, impact, and constant motion. Preparing rigging operations for those conditions requires choosing the right materials, protecting that equipment from the elements, and maintaining it to prevent premature failure and ensure safe lifts.

Recognize Environmental Stressors

Many factors influence the service life of a wire rope. Many of them, such as load and duty cycle, are present in every application. In extreme environments, hazards can come from every direction.

Heat: High ambient temperatures or proximity to welding arcs, furnaces, or exhaust systems can degrade synthetic fibers and alter the metallurgical properties of steel wire.

Chemicals and salt: Acids, alkalis, solvents, and salt water attack protective finishes and the base metal. Synthetic fibers can absorb chemicals, while steel components corrode in the presence of salt and moisture unless properly lubricated.

Abrasion: Sand, dirt, and rough surfaces remove protective coatings and damage outer wires or fibers. Fine abrasive dust is especially harmful because it works its way into strands and over sheaves. Contact with sharp edges accelerates wear and can cause synthetic fibers to cut.

Wind and dynamic loads: Gusts and sudden changes in load direction create shock loads and bending fatigue. Vibration from pumps or machinery can also introduce oscillating stresses.

Load history: Past overloads, kinks, or shock loads can leave hidden damage in wire ropes, chain slings, and hardware. Understanding how equipment has been used, not just how it looks today, helps determine whether it is suitable for continued use.

By cataloging these stressors and the frequency of exposure, rigging supervisors and lift planners can make informed choices about materials and maintenance plans.

Material Selection: Steel vs. Synthetic

Steel Wire Rope

Steel wire rope remains the industry standard due to its high strength, resistance to cutting, and ability to tolerate abuse. Galvanized or stainless constructions improve corrosion resistance, and properly selected steel ropes can operate in temperatures that would melt synthetic fibers.

The drawbacks are weight and corrosion. Steel ropes are heavy to handle and, without consistent lubrication and inspection, moisture and salt can cause rust that weakens the rope.

High-Performance Synthetic Rope

Research funded by Oregon OSHA shows that ultra-high molecular weight polyethylene (UHMWPE) ropes provide an attractive alternative in many applications. These high-modulus polyethylene fibers have strength comparable to steel at a fraction of the weight. Their buoyancy and low friction make them easier to deploy and retrieve.

However, synthetic ropes can be easily cut by sharp edges and are sensitive to heat and certain chemicals. They also have a different failure mode than steel. Instead of showing obvious broken wires, internal fiber damage can accumulate until the rope suddenly fails. That makes inspection and conservative retirement criteria critical. Lift planners must weigh the weight savings against the vulnerability to cuts and heat.

Fiber Rope and Synthetic Web Slings

Fiber rope slings are valued for their flexibility and ability to conform to loads. They can be easier on delicate surfaces, and synthetic web slings distribute load over a wider bearing area, which helps protect loads with sensitive finishes. Their ability to mold around irregular shapes reduces the risk of crushing the load.

These should be used only on light loads and in environments that do not subject them to severe heat, abrasion, or sharp edges. Synthetic slings must not be used where there is a risk of exposure to high heat, weld spatter, or aggressive chemicals without adequate protection. Synthetic slings are also vulnerable to ultraviolet (UV) exposure, chemicals, and weld spatter. Discoloration, stiffening, or hard spots indicate chemical or heat damage and are cause for removal from service. Frayed stitching, cuts, or visible damage to core yarns likewise indicate a loss of strength and require discarding the sling.

Lubrication and Maintenance

Lubrication reduces friction between wires, prevents corrosion, and helps distribute load among strands. In extreme environments, lubrication makes the difference between a rope that reaches its design life and one that fails early. The right lubricant, applied correctly and at the right frequency, can significantly extend wire rope life and prevent loss of strength due to premature wear or corrosion.

The Pacific Northwest National Laboratory Hoisting and Rigging Manual emphasizes that inspection and lubrication go together. Each inspection is an opportunity to clean the rope, check for damage, and evaluate whether the current lubricant and schedule are adequate for the environment. Changes in operating conditions, such as increased exposure to heat, chemicals, or moisture, may mean a different lubricant is required and that maintenance frequency needs adjustment.

Practical lubrication programs should be tailored to operating conditions.

Select the right lubricant. Use products formulated for wire rope or chain that provide corrosion resistance without attracting excessive dirt. In cold environments, choose lubricants that remain fluid at low temperatures. In high-temperature applications, use lubricants that will not evaporate or carbonize. Avoid products that could contaminate process fluids or increase friction excessively, which can impede braking on drum wraps.

Clean before lubricating. Remove dirt, old grease, and debris from the rope using wire brushes, compressed air, or approved solvents so the new lubricant can reach internal strands.

Apply regularly based on usage. There is no single rule for how often to lubricate. Instead, base intervals on operating hours, environmental conditions, and inspection findings. More frequent lubrication is needed in corrosive environments or when the rope cycles over sheaves frequently.

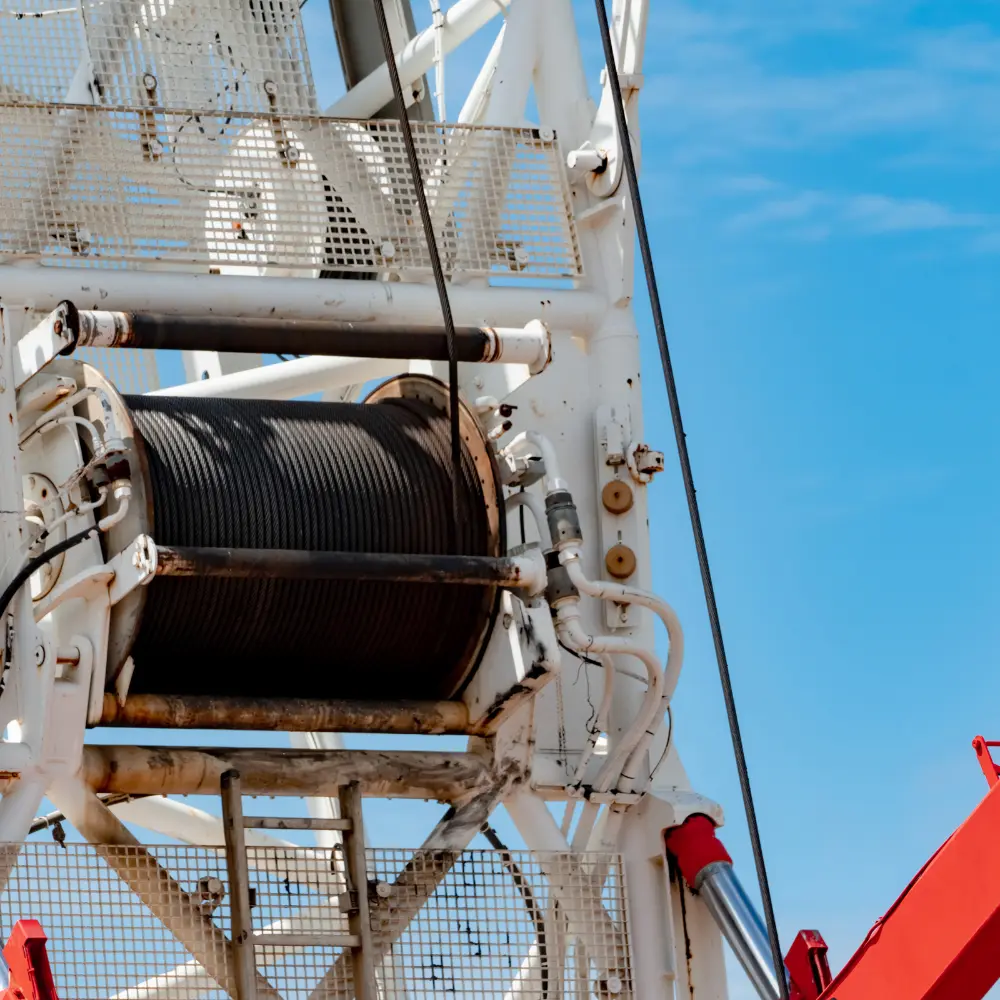

Protect during storage. Store ropes in a dry, well-ventilated area off the ground. Cover them to shield from rain, snow, and direct sunlight. For outdoor storage, protect reels or coils with breathable covers and avoid moisture accumulation, since it can freeze and damage strands.

Inspection and Retirement

Regular inspection is critical in extreme environments. The most noticeable conditions requiring immediate retirement of wire rope slings include:

- Severe corrosion

- Localized wear (shiny spots)

- Reduction in outer wire diameter of roughly five percent of the original rope diameter, in line with standard retirement charts

- Damaged or displaced end fittings

- Distortion

- Kinking

- Birdcaging

- Excessive broken wires

Inspect not only the working length but also the sections near terminations, around sheaves, and at points of contact with drums or hardware. For chain slings, look for stretch, bent or cracked links, and damaged hooks. Check for broken stitching, melting, cuts, or chemical burns on web slings.

Records should document inspection dates, findings, and corrective actions. Tracking this information helps demonstrate compliance during audits and helps predict retirement trends.

Keeping Wire Ropes and Rigging Supplies Safe and Functional

Operating in harsh environments requires thoughtful preparation rather than relying on standard rigging practices. Whether a job calls for steel wire rope, high-performance synthetic rope, or the flexibility of fiber slings, each choice brings trade-offs in weight, durability, and resistance to heat, chemicals, and abrasion.

Choosing the appropriate material involves balancing strength, environmental resistance, and ease of handling. Lubrication and maintenance programs must be tailored to local conditions. Above all, consistent inspection and adherence to conservative retirement criteria, including limits on diameter reduction and visible damage, keep rigging equipment performing safely and reliably, protecting workers, loads, and equipment in the toughest conditions.

Related Reading