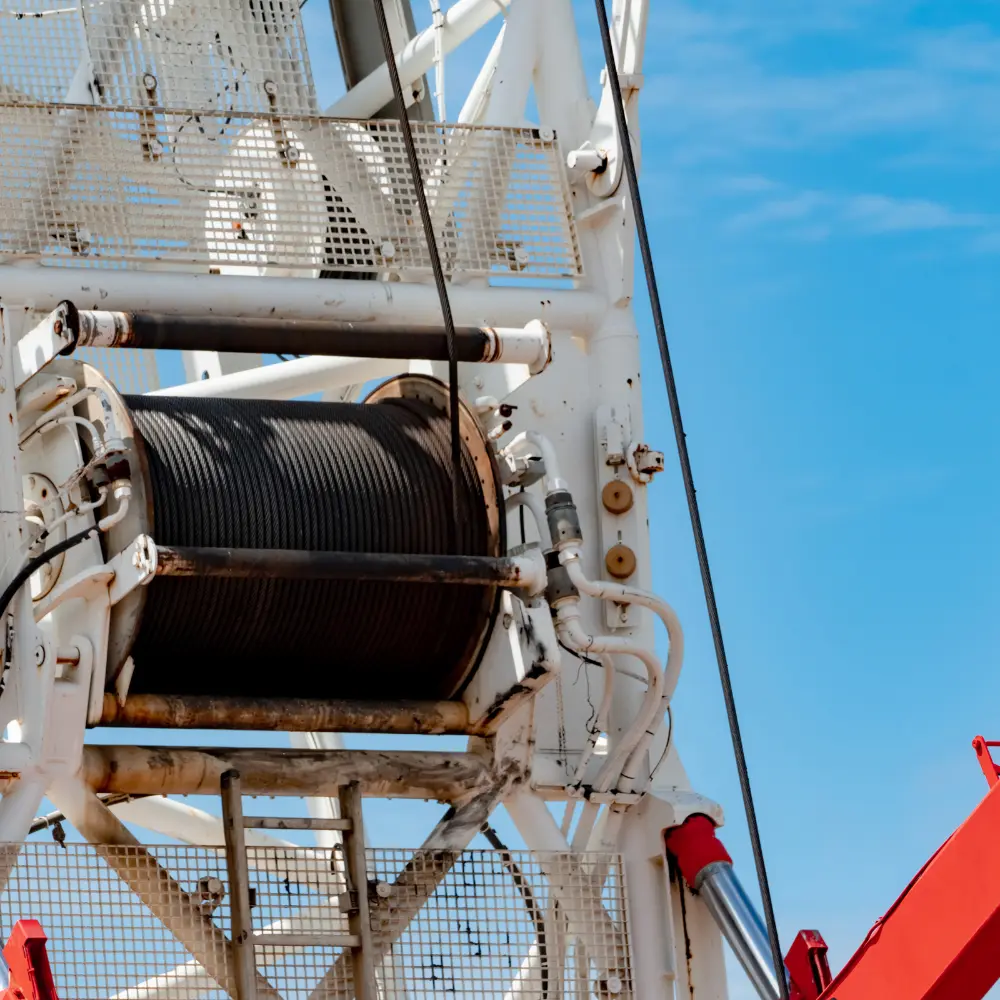

At Bilco Group, selecting between our steel wire rope and high-performance synthetic rope is no longer a matter of tradition. Our modern synthetic ropes made from ultra-high molecular weight polyethylene (UHMWPE) fibers can match the tensile strength of steel rope while weighing only one-ninth as much. This dramatic weight savings changes how cranes, winches, and rigging crews operate: lighter lines reduce equipment wear, speed up rigging, and can increase payload capacity. Yet synthetic ropes also come with limitations, including susceptibility to cuts and heat, and they cost significantly more than steel. Understanding when the benefits outweigh the drawbacks is essential for making safe, cost-effective decisions.

Strength-to-Weight Ratio and Handling

The primary reason operators choose synthetic rope is its superior strength-to-weight ratio. Research funded by Oregon OSHA found that UHMWPE synthetic rope of the same diameter as steel rope is approximately equal in breaking strength yet weighs only one-ninth as much. For cranes and hoists, reducing line weight means crews can lift heavier loads without exceeding equipment ratings. A lighter line reduces stress on sheaves and drums and can allow operators to downsize related hardware.

Lighter ropes also reduce manual handling effort, minimizing fatigue and the risk of musculoskeletal injuries. Because synthetic fibers have low stretch and store less energy than steel, they are less likely to recoil violently if they fail, improving safety during dynamic lifts. In applications where load control is critical, the low elasticity of synthetic rope provides more precise positioning. By contrast, the higher mass of steel rope contributes to momentum and can make sudden stops more challenging to control.

Durability and Environmental Resistance

Synthetic ropes offer excellent resistance to water, salt, and many chemicals thanks to polymer coatings. UHMWPE fibers are non-corrosive and do not rust when exposed to moisture or seawater. The same Oregon research notes that synthetic ropes have low friction and do not develop “jaggers” (broken wire ends) that can injure workers. These properties make them ideal for marine towing and for environments where cleanliness is important, such as food processing or laboratories.

However, these benefits come with trade-offs: synthetic fibers can be easily cut by sharp objects, cannot withstand high temperatures, and may degrade under prolonged UV exposure. Sharp edges can quickly slice through a loaded synthetic line. Operators should avoid routing synthetic rope over sharp edges, weldments, or rough surfaces and should install protective sleeves or fairleads to prevent abrasion. When work involves welding, grinding, or other heat sources, steel rope is the better choice because it resists sparks and elevated temperatures. Steel wire rope remains the preferred option for operations involving grinding surfaces, weld spatter, or conditions that could compromise synthetic fibers.

Maintenance, Inspection, and Safety

Maintenance requirements depend on the rope material. Steel ropes are machines with many moving parts; periodic lubrication reduces friction between strands and prevents corrosion. Operators must select lubricants compatible with the rope’s core and apply them uniformly to ensure they penetrate the core.

Synthetic fibers do not rust or require lubrication, but they do require vigilant inspection. Synthetic ropes should be checked for glazing (shiny, melted patches), UV damage, fiber fusion, cuts, abrasion, and internal wear. If the rope has been exposed to chemicals or extreme heat, examine the fibers for discoloration or brittleness. Steel ropes should be inspected for broken wires, corrosion, diameter reduction, kinks, birdcaging, and deformation of fittings.

Training is crucial: riggers should be able to recognize damage modes unique to each material, document inspection findings, and retire ropes when necessary. Establishing routine inspection intervals—daily visual checks and periodic detailed inspections—ensures that damage is identified early and removed from service before failure occurs. Maintaining a clean, dry storage area and protecting ropes from direct sunlight will prolong the life of both synthetic and steel ropes.

Economic Considerations and Lifecycle Costs

The initial purchase price is often the biggest barrier to adopting synthetic rope. Oregon research indicates that UHMWPE rope costs two to four times more than steel rope of equivalent diameter. However, a simple cost comparison at the time of purchase does not tell the whole story.

In many operations, lighter ropes translate to tangible savings: crews can handle lines more quickly, reduce rigging time and fatigue, and potentially lift heavier loads without upgrading cranes or winches. Synthetic ropes eliminate the need for lubrication and are not susceptible to corrosion, which can lower maintenance expenses and reduce downtime associated with cleaning and re-lubrication.

On the other hand, synthetic ropes may require more frequent replacement if used around sharp edges, abrasive surfaces, or in high-heat environments. Decision makers should calculate the total cost of ownership by factoring in productivity gains, reduced equipment wear, handling efficiencies, and the likelihood of damage in specific applications. For some projects, the longer service life and lower maintenance of steel rope will outweigh the benefits of weight reduction.

When Synthetic Outperforms Steel

High-performance synthetic rope makes sense when weight reduction, corrosion resistance, and ease of handling are top priorities. Offshore vessels choose synthetic mooring lines to reduce equipment weight and improve stability. Towing operations benefit from lightweight lines that float, coil, and stow easily. Remote construction and mining sites may use synthetic rope to increase hoist payload without upgrading cranes and to minimize worker fatigue during rigging.

Situations that involve frequent handling, long lengths of rope, or operations over water often favor synthetic materials. By contrast, steel wire rope remains the standard for high-temperature environments, heavy abrasion, sharp edges, and applications where well-established inspection protocols are mandatory.

Choosing the right rope involves balancing strength requirements, environmental exposures, handling needs, and budget.

Comparison of Synthetic vs. Steel Rope

|

Factor

|

UHMWPE Synthetic Rope

|

Steel Wire Rope

|

|

Weight

|

Approximately one-ninth the weight of steel for the same diameter; easy to handle and transport

|

Heavy; increases overall system weight and handling effort

|

|

Strength

|

Comparable to steel of the same diameter

|

High; proven in high-load applications

|

|

Heat resistance

|

Poor; cannot withstand high temperatures or weld spatter

|

Good; tolerates elevated temperatures and sparks

|

|

Abrasion & cut resistance

|

Vulnerable to sharp edges and abrasion; requires protection sleeves

|

Excellent against abrasion and cuts

|

|

Corrosion & moisture

|

Non-corrosive; resists water, salt and many chemicals

|

Can corrode without proper lubrication and maintenance

|

|

Cost

|

Two to four times more expensive initially; may reduce total costs through handling efficiencies

|

Lower upfront cost; requires lubrication and may have higher long-term maintenance

|

|

Typical use cases

|

Marine mooring, towing, remote lifting and applications where weight matters

|

High-temperature work, heavy abrasion, sharp edges and well-established protocols

|

The Right Ropes for the Job

High-performance synthetic rope offers compelling benefits for certain rigging operations. Its unmatched strength-to-weight ratio allows crews to handle lines more easily and lift heavier loads without exceeding equipment ratings. Synthetic materials resist corrosion and chemical attack and do not produce sharp wire ends, making them safer and more comfortable to work with.

These advantages come with trade-offs: synthetic ropes are vulnerable to cuts and high temperatures, and they cost more than comparable steel ropes. Operators must protect synthetic lines from sharp edges, inspect them for damage unique to fiber construction, and balance the higher purchase price against potential savings in handling and maintenance.

In high-temperature or highly abrasive environments, steel wire rope remains the better choice. By understanding the strengths and limitations of each material and matching them to the application, rigging supervisors can select the rope that delivers the best performance, safety, and value.

Related Reading