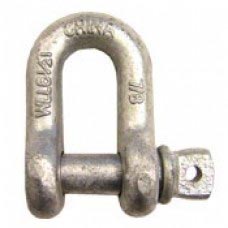

Rigging supplies such as shackles and clips are critical in securing and moving heavy loads in lifting and hoisting operations. To ensure the safety of both personnel and equipment, these tools must be maintained in peak condition. By focusing on regular inspections, proper usage, and correct storage practices, businesses can extend the lifespan of their rigging hardware, reducing downtime and avoiding costly replacements. This article provides essential tips for maintaining the durability and performance of shackles and clips, which are critical components in any rigging operation.

Rigging supplies such as shackles and clips are critical in securing and moving heavy loads in lifting and hoisting operations. To ensure the safety of both personnel and equipment, these tools must be maintained in peak condition. By focusing on regular inspections, proper usage, and correct storage practices, businesses can extend the lifespan of their rigging hardware, reducing downtime and avoiding costly replacements. This article provides essential tips for maintaining the durability and performance of shackles and clips, which are critical components in any rigging operation.

How Frequently Should You Inspect Rigging Supplies?

Rigging supplies, particularly shackles and clips, should undergo regular inspections to identify signs of wear or damage before they become a safety hazard. This proactive approach, recommended by industry best practices, involves pre-use inspections every day these items are in service. By adopting this proactive stance, you can ensure the early detection of potential failures, ultimately extending the lifespan of rigging hardware.

For shackles, focus on:

- Signs of Deformation: Check for bending or warping, particularly around the pin and body. Deformed shackles are structurally compromised and should be removed from service.

- Cracks and Corrosion: Look for cracks, pitting, or rust, especially where the shackle experiences the most stress. Corrosion can significantly weaken the material, leading to failure under load.

- Pin Functionality: Ensure the shackle pin threads smoothly and properly seat. A misaligned or loosely seated pin can cause uneven load distribution, weakening the shackle’s capacity.

For wire rope clips, inspect for:

- Correct Torque on Nuts: Loose nuts reduce the clip’s ability to secure the wire rope properly. Regularly check and torque the nuts to maintain a solid grip to manufacturer specifications.

- Corrosion and Wear: Look for signs of rust or wear where the clip meets the wire rope. Corrosion can weaken the clip’s grip, leading to potential slippage.

Frequent inspections of shackles and clips prevent minor issues from escalating into significant failures, significantly prolonging their service life.

How Can Proper Usage Extend the Life of Shackles?

Correct usage of shackles is not just about ensuring their longevity; it's about maintaining safe operations. Improper handling, especially related to load angles, can rapidly degrade these essential rigging supplies. By adhering to correct usage guidelines, you can instill a sense of security and confidence in your operations.

- Avoid Loading at an Angle: Shackles are designed to carry loads vertically. Applying a load at an angle can drastically reduce their strength and lead to deformation or breakage. If an angular load is unavoidable, consider using a shackle with a larger capacity to compensate.

- Ensure Proper Pin Seating: Always verify that the shackle pin is correctly threaded and seated. Replacing the pin with a bolt or misaligned pin can compromise the shackle’s integrity, leading to equipment failure.

- Lubricate Pin Threads: Shackles exposed to harsh conditions, such as marine or chemical environments, benefit from regular lubrication to prevent seizing and rust. This simple maintenance practice can extend the lifespan of shackles by preventing corrosion from taking hold.

By following these usage guidelines, businesses can maximize the strength and durability of their shackles, reducing the likelihood of premature failure.

Best Practices for Maintaining Wire Rope Clips

Wire rope clips are critical parts of rigging hardware and require meticulous attention to ensure they perform optimally under load. Misuse or poor maintenance can result in slippage or even load failure, making proper installation and upkeep essential.

- Install Correctly: The U-bolt should always be positioned over the dead end of the wire rope, with the saddle placed on the live end. Incorrect installation— saddling the dead horse—weakens the clip’s holding power and increases the risk of slippage.

- Re-Torque After Initial Use: After the load has been applied for the first time, it’s common for the clips to settle, causing the nuts to loosen slightly. Be sure to re-torque the nuts after this initial settling to maintain a firm grip.

- Use the Recommended Number of Clips: The number of clips required depends on the diameter of the wire rope. For example, a 1/2-inch wire rope typically needs at least three clips to ensure a secure connection. Using fewer clips can reduce the rope's holding strength and increase the risk of failure.

Adhering to these best practices ensures the longevity of wire rope clips, preventing failures during critical lifting operations.

Why Proper Storage is Vital for Rigging Supplies

Storing rigging supplies correctly is just as crucial as using and maintaining them properly. Shackles and clips exposed to moisture, chemicals, or extreme temperatures can suffer from accelerated wear and corrosion, shortening their lifespan. By ensuring proper storage, you can feel reassured that your equipment is in top condition and ready for safe use when needed.

- Store in a Dry, Clean Area: Rigging hardware should always be kept in a dry, controlled environment to prevent moisture from causing corrosion. Rust can weaken metal components, reducing their capacity and lifespan.

- Avoid Exposure to Harsh Elements: If shackles and clips are used in corrosive environments (e.g., salt water or chemical plants), they should be cleaned and dried thoroughly before storage. Protective coatings can be applied to provide additional resistance to rust.

- Use Shelves or Containers: Storing rigging hardware off the ground helps avoid dirt, moisture, and physical damage. Shelving systems or designated containers designed for rigging supplies are ideal for keeping components clean and organized.

By adequately storing rigging supplies, businesses can ensure that their equipment remains in top condition and ready for safe use when needed.

Protect Your Investment by Caring for Rigging Supplies

Proper care is vital in industries where rigging supplies like shackles and clips are essential to lifting operations. By adhering to regular inspection schedules, ensuring correct usage, and storing equipment properly, businesses can significantly extend the lifespan of these critical tools. Taking these steps reduces the likelihood of unexpected failures, enhances safety, and protects your workers and investment in rigging hardware.

Related Reading